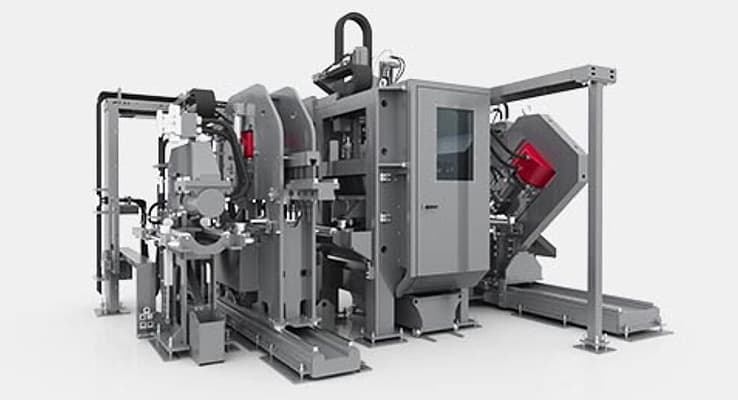

Tig Welding

The two flanges, which are located on the conveyor section opposite each other of the web's web, are rotated into vertical position by magnetic guide rollings. The three pieces can be moved to the right position by a hydraulic clamp. The operator manually joins them. The clamps can be released and the tack welded beam is sent to the welding station. After the initial adjustment of the clamp positions in the first beam beam, the operator controls all material movement through the control panel.

.jpg)